Nothing beats making your ideas tangible. Creating a product prototype is how you do that. This is the process that turns concepts into realities.

When you have a prototype, you can test, refine, and perfect your design before mass production. But it’s not always a straight path to get there. You need to plan, research, and adapt as you learn new information.

Many aspiring inventors rush through the prototyping phase. They might overlook important details or skip critical tests, only to end up paying for it later. A well-thought-out prototype, on the other hand, can save time, money, and headaches later.

In this guide, we’re going to talk about how you can prototype your product in five simple steps. Along the way, we’re going to share thoughts from industry experts who’ve been through the process.

How Product Manufacturing Works

Before you start working on a prototype, it helps to know what goes into product manufacturing. It starts, of course, with an idea. You come up with a clear concept and then you make a prototype.

Prototyping means creating detailed specifications, including those around materials, dimensions, and functionality. Depending on what you’re making, you might end up using computer-aided design (CAD) software.

Once the design is finalized, you’ll need to choose a manufacturer, assuming this isn’t something you can make in-house. Manufacturers vary in terms of capabilities, quality standards, and costs. So if you want great results, you’ll be doing a lot of research.

Your design might require special processes, like injection molding, CNC machining, or 3D printing. But that will all depend on what you’re making.

Once you find a few manufacturers you like, then you request quotes. Once you review those, you settle one you like best and then start production. This might involve doing a small test run to make sure everything goes OK. If the sample run turns out well, you can move on to full-scale production.

Bearing all that in mind, we’ll now share advice from experts on common mistakes to avoid during the prototyping and manufacturing processes.

5 Tips Before You Start Manufacturing

When you start having product manufactured for you, it can be stressful, even if you know what you’re doing. But with some forethought, you can avoid common issues.

1. Know your customers.

Jason Wingate, CEO of Emerald Ocean Ltd., illustrates this especially well in a story he shared with us. He says, “a few years ago we released the Rotary Thread tool, a thread filing tool that was revolutionary and nothing was like it on the market. It could file threads quicker and faster than anything. We sold (and still sell) to Lowe’s and Home Depot in the USA, and Canadian Tire in Canada.”

“But sales were not as good as we expected. Why? Because the customers of most retail chains don’t need a thread filing tool most of the time. If a nut or bolt comes loose, they just buy a new one for a few cents.”

Wingate’s team was ultimately able to pivot into a much more profitable niche with time. But he stresses the importance of knowing your customer before total commitment to a certain course of action. “If the customer doesn’t have a problem or need your product – you need to reflect on that and find out what they do need and how your product fits.”

2. Start small and iterate quickly.

You’re not going to get everything right the first time. Multiple sources stated this to us, perhaps best said by Jorge Argota, a marketing consultant with a background in product development.

Argota says it’s best to “start small with your prototypes to keep costs down and iterate quickly based on feedback. Engage potential users early in the process to make sure the product meets their needs. Keep detailed records of all changes and decisions during the prototyping phase, it will help you in future development.”

He also emphasizes that it’s important to be flexible with your design, and to adapt to challenges or new opportunities as they come.

On a related note, Ryan McDonald, COO of Resell Calendar, states that it’s important to not “forget packaging and branding during the prototyping process. Early consideration of these elements can significantly impact the perceived value of your product. At Resell Calendar, we’ve found that your product’s resale value is much improved by appealing, well-designed packaging.”

3. Don’t underestimate the costs.

One unfortunately common issue that product creators run into is underestimating costs. It’s easy to overlook certain expenses, especially when they’re not obvious. But hidden or not, costs associated with material testing, design revisions, and multiple iterations add up. So does gaining access to specialized tools or machinery, like plastic molds.

When asked about mistakes best avoided, Argota said that “I underestimated costs early on, didn’t vet some manufacturers well enough and sometimes rushed through the prototyping phase without enough testing.”

The learning curve is formidable and making mistakes is common. But nevertheless, Argota emphasizes that “miscommunication about product specs led to some costly mistakes. Looking back better planning and clearer communication would have saved a lot of trouble.”

When in doubt, assume manufacturing – including prototyping – will cost more than you think.

4. Don’t hurry the process.

Another tempting mistake is to rush through the prototyping process. But ironically, this can end up wasting more time, in addition to leading to costly mistakes. When you’re in a hurry, it’s easy to skip steps like testing, refinement of the design, and gathering feedback.

“Anyone beginning their own product prototype should never hurry the process,” says McDonald. “Spend time evaluating your prototypes in real-world conditions. Don’t be afraid to iterate, as every version should improve upon the last. Keep your target market in mind throughout the process. In the end, the product must fulfill the needs and wants of your customers.”

5. Consider hiring a broker.

You don’t necessarily have to manufacture your own products. In fact, you have the option to hire a broker to assist.

When asked what he would do differently, Wingate stated that “if I could change anything – first I would get a good broker. Without one we were just going back and forth ourselves looking up and trying to evaluate manufacturers, but a good broker will have that knowledge and possibly existing relationships already.”

5 Steps To Create A Product Prototype

It’s premature to start prototyping before you understand the underlying logic of manufacturing and prototyping. Having covered that in the previous sections, we can now provide a list five steps that you can follow to get started with prototyping.

1. Create the best prototype you can alone.

Everyone we talked to, independently of one another, agreed that it was vitally important to have a clear vision of what you want to make. One great way to do that is to make the best prototype you can on your own. This isn’t a substitute for a sample run, but rather a way to clarify your thinking.

McDonald says, “we’ve found that having a clear vision is crucial when prototyping products. First, we create detailed sketches and 3D renderings of our product ideas. This visualizes the end result, allowing us to identify potential issues early on. After that, we create physical prototypes. For smaller items, we use 3D printing, and for larger ones, we work with local craftsmen.”

Argota has a similar process, saying that he and his team would create “a basic version of the product using basic materials to test the idea. Depending on the product complexity and requirements, I used 3D printing, CNC machining, or even handcrafting. This stage [involved] a lot of iterative testing and gathering feedback to refine both design and functionality.”

Even Wingate, who advocates for working with a broker says that “while I don’t usually prototype the products myself – the general way is that we try to see if we can ‘throw it together’ as a prototype in-house using CAD drawings and, if possible, a 3D printer (of course – this depends on what you’re trying to create).”

2. Find a similar product.

Once you have a sense of what your product will look like, try to find similar ones. Buy them, if need be. You want to analyze similar products and try to understand how they are made.

If you’re not sure how a product is being made, you can try looking for “making of” or “X being manufactured” videos on YouTube. You might also have some luck looking for how to blogs or even searching for patents.

Even if you are unable to tell how specific products are made, finding similar ones will allow you to describe what you want to a manufacturer. They may be able to reverse engineer a product that already exists.

Sometimes, you can even find the manufacturer of products you like. That gives you chance to reach out to a company whose work you’re already familiar with.

3. Shop for materials.

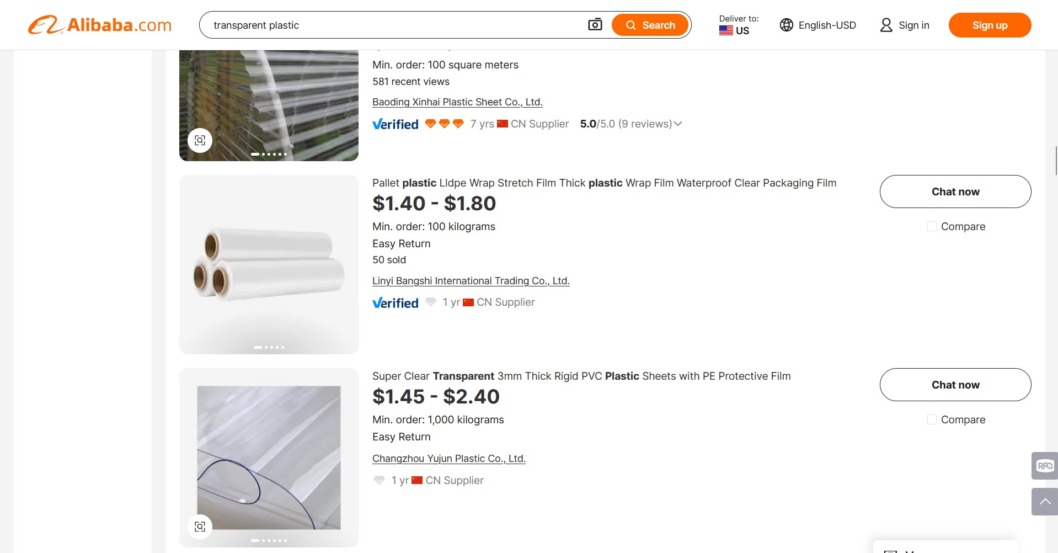

Once you have similar products in hand, start researching material options through manufacturers’ catalogs, sourcing platforms like Alibaba and ThomasNet, and by consulting with industry experts if needed.

As you research, keep in mind that tariffs on imports — especially from China — have risen sharply in 2025. It’s wise to check tariff classifications (HS codes) for your intended materials and consider alternate sources, like Mexico, India, or Vietnam, if costs are too high. Bear in mind that some materials are subject to higher tariffs than others, so you may be able to save on tariffs if you choose materials carefully.

The specifics of your material research process will differ greatly depending on the nature of the product you are manufacturing, but the basic information provided above is useful in most cases.

For example, if you know you need transparent plastic, you can figure out a more specific name using this method. The screenshot below shows you what happens when you look for “transparent plastic” on Alibaba. You have options ranging from food-grade R-PET plastic to cast acrylic to polycarbonate…the list goes on.

When asked about best practices on material selection, McDonald says that “we consider cost, durability, and user experience. To evaluate performance and quality, we often order samples from several suppliers. For electronics, we prioritize components that satisfy industry standards and have a track record of reliability. Regarding clothing and accessories, we pay close attention to materials that provide longevity as well as comfort.”

Argota has a similar method, saying that in his prior career, “material selection was driven by durability, cost, availability and how well the material suited the product’s purpose. I did some initial research by consulting with material experts and engineers and factored in sustainability if that was a priority. Prototyping with different materials helped me make a more informed decision.”

Wingate emphasized the importance of “research, research, research.” And indeed, his emphasis is well placed, since material requirements vary widely based on product, price, market, your target audience, and a variety of other factors.

4. Look for a manufacturer.

When the situation calls for it, it’s a great idea to make your own prototype. But your own in-house prototype is no replacement for a true sample of a manufacturer’s work. So it is very important to note that prototyping will also involve finding a manufacturing partner.

This can be an in-depth process. According to Argota, “finding the right manufacturer required researching companies that specialized in my type of product. I used online directories, attended industry trade shows and reached out to my contacts for referrals. I made sure to evaluate each manufacturer’s capabilities, quality standards, communication style and reliability before making a decision.”

McDonald says that his team has “had success with platforms like Alibaba and GlobalSources. These platforms let us connect with many different manufacturers and evaluate their capacity and cost performance. Whenever possible, we also go to trade events since they offer great chances to meet manufacturers personally and see their work firsthand.”

To add to the above, we believe it is best practice to contact multiple manufacturers so that you can compare quotes. Alternatively, you can consider Wingate’s advice to hire a broker.

Most important of all: never commit to a manufacturer based solely on their claims or portfolio. Request samples of similar products they’ve made, ideally using materials comparable to your requirements. Pay attention to finish quality, dimensional accuracy, and consistency between multiple samples.

Consider visiting facilities if feasible, or hiring third-party inspection services. Many manufacturers excel at producing samples but struggle with consistent quality at scale. Ask about their quality control processes, testing equipment, and how they handle defective units.

Document everything during this evaluation phase. These records become valuable if quality issues arise during production.

And again, it bears repeating: rising tariffs on Chinese goods in 2025 have also made it increasingly important to explore manufacturers in regions with lower import duties. Some creators are shifting to Mexico, Southeast Asia, or even U.S.-based options for smaller production runs.

5. Request quotes.

Once you have a clear idea of what you need to manufacture and what materials you need to use to make it, then you can request quotes. You want multiple quotes from multiple manufacturers so you can compare them and make a smart decision.

“To get quotes I reached out to several manufacturers with detailed specifications of the product, including drawings or CAD files, material requirements and expected quantities,” says Argota. “Comparing these quotes helped me understand the market rates and negotiate better terms. Having all the info ready upfront made the process smoother.”

This isn’t a process you can shortcut. As McDonald states, “though it can take time, the quote request procedure is necessary to get the best value. Usually, we reach out to various manufacturers with detailed product specifications. We request quotations breaking out labor, material, and any additional fees.”

This thorough approach has a lot of benefits. “This lets us compare offerings more easily. We also consider production capacity, quality control measures, and communication responsiveness as the lowest bid as not necessarily the best choice.”

If this process intimidates you, take heart. According to Wingate, “quoting isn’t too hard.” He further states that “you’ll get feedback and pricing from a variety of suppliers, and if you did your research (or had your broker do it for you), you can select from there.”

Final Thoughts

Making a great product prototype requires patience, planning, and willingness to adapt. The goal here isn’t just to bring an idea to life, but to refine an idea until it’s the perfect fit for your customers. If you follow the steps in this article, you’ll be well on your way to doing exactly that.

Don’t rush the process and don’t underestimate its complexities. Doing that can lead to delays and extra expenses. Take your time and do things right. Test, gather feedback, and improve at every stage. If you go through this process and you’re careful and attentive to detail, you won’t just make your idea tangible – you’ll make a really good product that people desperately want to buy.