Have you ever ordered something online and wondered how exactly it got to your house? You’re certainly not alone—people may shop online a ton, but the order fulfillment process is still a little opaque.

Supply chain management, done well, is a bit like magic. Online shoppers can go their whole lives without really understanding how items get from Point A to Point B. And that’s the way we like it!

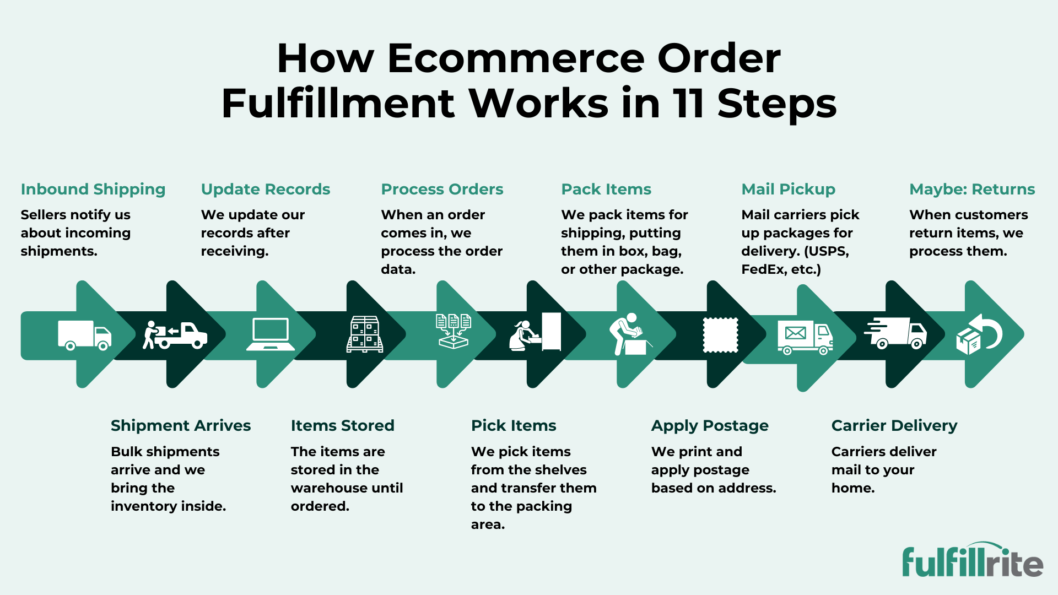

But still, you might be curious about how the whole thing works. So to satisfy your curiosity, here are the 11 order fulfillment steps that take place within the walls of our warehouse—and other warehouses like it—that make online shopping possible.

11 Steps in Ecommerce Order Fulfillment

1. Sellers notify us about incoming shipments.

Before we can talk about what happens when you click “buy”, we need to talk about how goods wind up in our warehouse in the first place! Sellers have to ship them to us in bulk, which they do by booking freight.

Freight is how you get large quantities of goods from one place to another, such as a manufacturer to a warehouse. Booking freight is a complex enough subject in its own right, which we write about in detail here. Suffice it to say, when something happens in the world of freight—like a boat getting stuck in a canal—it can really slow down the flow of goods from one place to another!

In any case, in order for us to prep our warehouse for a big shipment, we have sellers send us an ASN, or advance shipping notice. That basically tells us when they’re shipping items in and what we can expect to find in the truck. This allows us to make sure we have enough people working a given shift to unload the truck in a timely manner.

The process is the same even in other countries. For example, Adayra Lopez, Vice President of Sales at InterFulfillment, a Canadian fulfillment center, describes a similar process for knowing when new orders come in.

“Orders are seamlessly transmitted to your [fulfillment center] software through integration with your shopping cart, ERP system, or other platforms,” says Lopez. “This eliminates the need for manual order uploads, though that option remains available if you prefer to start manually before integrating. Once an order is processed, the tracking number is automatically sent back to your shopping cart, ERP system, or other platforms through the integration.”

It’s also worth noting here, in light of changes to trade policy, that by the time sellers send inventory to us—a US-based warehouse—tariffs are already paid on the wholesale value of the item. That means we can ship to everyone in the US without the individual buyers paying tariffs or customs.

2. Bulk shipments arrive and we bring the inventory inside.

When the truck arrives, goods are typically packed in boxes. If there are enough goods, the boxes will be packed on pallets and possibly shrink-wrapped to the pallets.

Depending on the size and number of the boxes, we may use conveyors to slide boxes quickly from the truck into the warehouse. Alternatively, we may use pallet jacks to move entire pallets of goods within the warehouse. With either method, the goal is to ultimately move inventory to a designated place in the warehouse where they will be stored for the long term.

3. We update our records after receiving.

Once we receive goods, we make to update our system to reflect where we are going to store them. This makes it easy to know where to go when we need to retrieve items for order fulfillment. We also double-check to make sure we received the correct number of boxes or pallets based on the information included on the ASN.

4. The items are stored.

This part is straightforward. Either by hand or by using machinery like a pallet jack, we physically store the items where they need to go.

5. When an order comes in, we process the order data.

Now we can get to the part where you’re involved! We had to set the stage before your part could be played, because an order going to an empty warehouse simply cannot be fulfilled.

When you place an order online with a company that is using a fulfillment warehouse, a lot of things happen when you click that Buy button. The store will collect payment from you, and your shipping information as well as information about the order itself is sent to the fulfillment company. The specifics of how this happens differ based on what software the company is using and which fulfillment company they’re working with.

Let’s use a simple and common example for the sake of conversation. Say you order 10 blue baseball caps from a local Shopify store. Your mailing address is sent to us via a Shopify-Fulfillrite integration. Along with your mailing address, we also see which SKUs—unique items—you ordered along with quantities for each.

At this point, we now know exactly what we need to look for in the warehouse, where we can find it, and to whom we need to send it.

6. We pick items from the shelves.

At this point, we look for the blue baseball caps. We check our system to see where we stored them. Then a warehouse worker goes to pick them up and bring them to the shipping table.

During this process, we scan the items so we know how many we are taking out of inventory. This allows us to keep a pretty accurate tally of how many items we have on hand.

It’s worth noting that fulfillment centers also tend to be more cost-efficient than DIY shipping. According to Adayra Lopez at InterFulfillment, “their ability to leverage economies of scale plays a significant role. By managing large volumes of inventory for multiple clients, fulfillment centers can spread fixed costs—such as warehousing and equipment—over a larger base, effectively reducing the cost per unit.”

This “economies of scale” effect is why so many businesses—from small Shopify stores to mega-stores like Costco—rely on fulfillment centers instead of handling shipping in-house.

7. We pack items for shipping.

Once the items are delivered to the packing table, we determine how best to prep them for the mail. Breakable items need to be placed in rigid boxes and wrapped in cushioning material like bubble wrap. Other items, like T-shirts, can simply be put in polybags.

Choosing the right packaging can be a surprisingly complex topic in its own right. Suffice it to say, our goals are to pack items in the smallest packages possible while providing adequate padding so they items don’t break in the mail.

8. We print and apply postage.

Choosing the smallest package possible is important. Postage prices are determined by the weight and size of the package, so we naturally want to save our clients—the companies you order from – as much money as possible.

We weigh packages before we print postage and measure them as well. This allows us to buy and print the amount of postage. Depending on where we’re sending to, we may use a carriers such as UPS, USPS, or FedEx. For international shipping, we may use DHL or Asendia. Still in other cases, we may use regional carriers such as PCF (which serves just the northeastern US).

Once we print the postage, we apply it to the package and then prep it for pick-up.

9. Mail carriers pick up packages for delivery.

Because of the amount of packages we ship, carriers stop by our warehouse multiple times a day. Before they arrive, we sort packages based on carrier. That is to say, UPS packages go in one bin, USPS packages in another, and so on.

That way, when the carrier arrives, they take the bin full of goods and it’s a very short stop for them. This is where our work ends and mail carriers’ work begins.

10. Carriers deliver mail to your home.

Mail delivery is a complex subject in its own right. Suffice it to say that mail carriers each have their own hubs and sorting facilities. The trucks that collect packages from warehouses like ours all go to hubs/sorting facilities. At that point, packages are prepped to go from hub to hub. This is what’s happening when you see a package go from Los Angeles to Las Vegas to Houston and so on as it gets closer to your house.

Eventually, when your package arrives at the closest hub to your home, it is prepped for last-mile delivery. That’s when your local postal carrier picks up the package and drops it off at your place!

It’s at this point that order fulfillment is complete!

11. When customers return items, we process them.

Or is it? As many as 15-40% of online purchases are returned, which is a very wide range, yes, but even 15% is a lot!

That means the company that you shopped from needs to have a good, simple process in place for when items are returned.

Here is what the process usually looks like, though it may vary from store to store. The customer will request to return the item. They print a return label and a local carrier picks up the package.

The carrier delivers the item back to our warehouse. From there, we follow instructions given to us by the seller on what to do with returns. Sometimes we put them back into stock and sometimes we throw them away. It depends entirely on the nature of the item itself and the seller’s instructions.

Either way, returns are an important part of the order fulfillment process too, even if it’s easy to forget about them!

Final Thoughts

Ecommerce order fulfillment is a complex, multi-step process. But all these steps serve a clear purpose—moving products smoothly from seller to customers. This is what makes it possible to order items from the comfort of your own home and receive them just two days later!