Order fulfillment you can trust for eCommerce and crowdfunding

- Fast, accurate shipping. We pick, pack, and ship your orders out the same day we receive them.

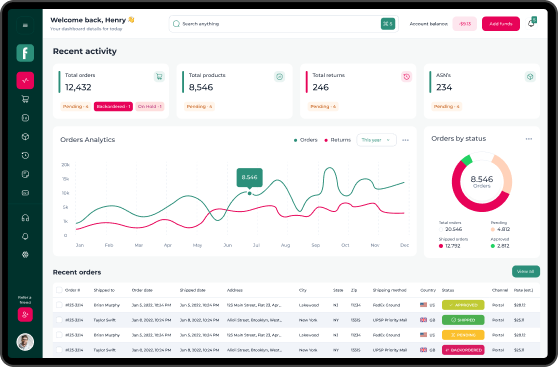

- Convenient software. Integrate with major eCommerce platforms like Shopify, WooCommerce, and Amazon. Track your orders and manage your inventory in real-time.

- Dedicated support. Every client gets a dedicated account rep who you can call or email anytime you have questions.

Our order fulfillment guarantees.

When it comes to shipping, specifics matter. We sweat the details so you don’t have to. Every Fulfillrite client benefits from:

- Fast, same-day shipping for orders received by 2 PM local time.

- A dedicated account rep who knows you by your first name.

- Access to additional services like returns, kitting, custom packaging, import assistance including customs clearance, custom projects, and more.

- Seamless integration with popular eCommerce & crowdfunding channels.

- Real-time order and inventory tracking through our intuitive and mobile-friendly online portal.

We’ve invested in a state-of-the-art facility to house and ship your merchandise

Fulfillrite’s warehouses are optimized to ship out your orders quickly and accurately. Everything from our highly trained staff to the way we store items to the machinery we use to pack orders is tailored for fast, reliable, cost-effective shipping.

We’re here to make your life easier, and your business more profitable

Fulfillrite helped solve all my problems!

I was in a real bind with no where to store my product. Fulfillrite really saved me and were super quick in helping me get set up with their services. Now, that I’m with them I love how easy they make running my business.

SEAMLESS AND STRAIGHTFORWARD

Sol at Fulfillrite was great to work with. He handled everything perfectly and fast! Their online portal was excellent to work with and integrates flawlessly with our businesses CMS/Website.

It was a really seamless and straightforward experience, and we look forward to continue working with them in the near future.

From the beginning several months ago, my experience with Steve at Fulfillrite has been the best customer service experience I’ve ever had. Here’s why:

1) He’s thorough: he sent me more information on the quotes than I asked for, just to keep everything crystal clear, and has done this multiple times.

2) He’s very quick to respond: I always hear back via email within a short time period…

3) He makes me feel like a priority…proof that Steve and Fulfillrite are here to serve me and make my experience smooth.

4) Small nobodies like me are still priorities: Frankly, my tiny startup business is not bringing in a lot of money for Fulfillrite right now. And yet, I feel like I’m their most important customer.

I brag about Steve – a real life customer service unicorn! – to my friends and my followers who supported my creative project on Kickstarter.com, because he’s genuinely that good! Assuming the rest of Fulfillrite functions this way, just know that if/when you ask questions, express concerns, or admit you’re ignorant and need help, you’ll be treated like royalty.

EXCELLENT FULFILLMENT PARTNER

Sol has been incredibly responsive and helpful throughout my entire experience with Fulfillrite. I reached out to Sol about fulfilling Kickstarter orders for a board game. Pricing was transparent.

I had a peculiarly shaped product and Sol took the time to experiment with different boxes/packaging to find the lowest cost/safest shipping method.

BEEN USING FULFILLRITE FOR ABOUT 1/2 A YEAR NOW FOR MY NEW SMALL BUSINESS AND LOVE IT.

Josh and his team are simply the best! Very easy to use their online portal, make payments and manage inventory.

IT’S JUST SO EASY! I CAN’T SAY ENOUGH POSITIVE THINGS.

Overnight shipping happens reliably (a completely new experience for me!). International shipping is reliable, fast, and cheap! Their website is smooth and intuitive. Getting products to them is easy. Adding new SKUs to the site is easy. They pass on their negotiated discounted shipping rates to me and my customers, and my shipping is cheaper than ever. It’s just so easy! I can’t say enough positive things about the company.

THE BEST IN THE ORDER FULFILLMENT BUSINESS.

Fulfillrite is amazing. Their shipping rates are unbelievably good. The speed of receiving new inventory and shipping new orders is lightning fast, and inventory shrinkage has been next to nil.

What few times I’ve needed support, it’s been top-notch. I highly recommend.

FULFILLRITE HAS BEEN AN AMAZING FULFILLMENT PARTNER, ALLOWING US TO FOCUS ON GROWING OUR BUSINESS.

Our account rep, Josh, provides excellent customer service whenever we have questions or special projects. Easy software setup, transparent pricing, orders come and packages get shipped out.

Since we switched to Fulfillrite we get a lot of compliments from customers on how fast they receive their orders. Would highly recommend to any other merchants!

A SIGNIFICANT IMPROVEMENT IN OUR BOTTOM LINE.

It has been nothing short of a pleasure and a significant improvement in our bottom line working with Fulfillrite. The two things we hoped to get with Fulfillrite were cheaper shipping costs and great customer service, and I’m happy to say that we found both.

Quick turnaround!

Fulfillrite has turned around all our orders quickly. Their app seamlessly integrates with our Shopify store, so orders are transmitted automatically.

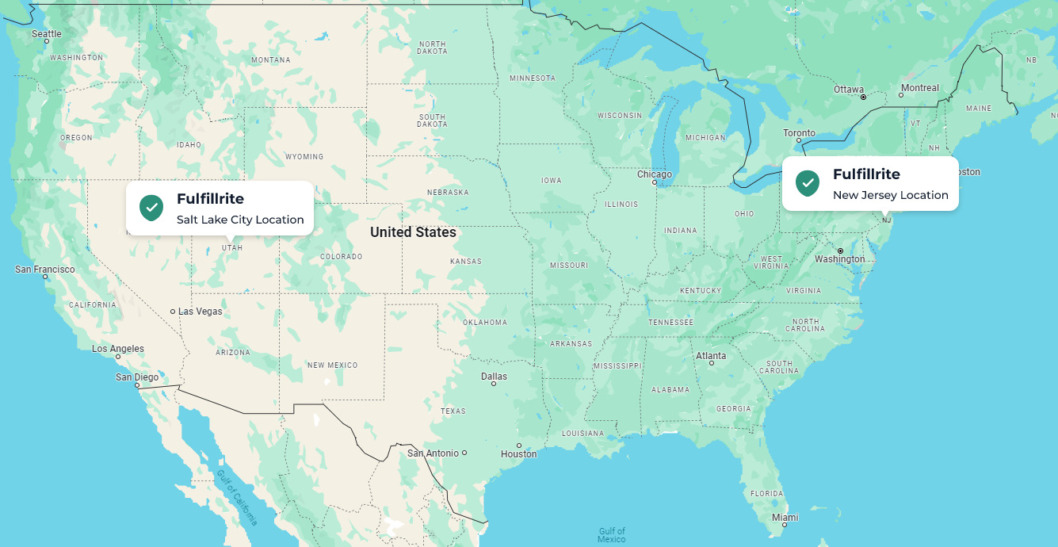

Warehouse Locations

Whether you’re shipping to Miami or Maine, Los Angeles or Kansas, your orders will go where they need to go quickly at a low price. With Fulfillrite, you have a fulfillment partner you can trust, all across the US.

Friday: 9AM - 2PM EST

Friday: 8AM - 1PM EST

Saturday: Closed

*Sunday: 9:30AM - 3:30PM

Utah location closed

Fulfillrite

825 Towbin Ave

Lakewood, New Jersey 08701

Fulfillrite

1950 N 2200 W

Salt Lake City, UT 84116

Services to help your business grow.

Order fulfillment is about picking, packing, and shipping orders. But your business might need more than “just the basics” to succeed, and Fulfillrite can support that.

We get to know our clients on a personal level. That means we can help you with special projects in addition to standard order fulfillment. Here are a few examples of additional services we provide.

Ecommerce Fulfillment

Ecommerce businesses have specific needs when it comes to order fulfillment, particularly around speed and precision. We've built our business and technology around these needs. With millions of eCommerce orders shipped, we pride ourselves on providing the most responsive, hands-on client experience in the industry.Repackaging & Refurbishing

Prep your products for resale with our repackaging and refurbishing services. Items don’t even have to leave the warehouse before they are ready to go out again.Kitting & Assembly

Streamline your supply chain with our kitting and assembly service. With them, we can guarantee cost-effective and accurate prep of multi-item orders and custom kits.Crowdfunding Fulfillment

If you need to ship backer orders for a Kickstarter, Indiegogo, Gamefound, or any other kind of crowdfunding campaign, we can help you do that. We understand the complexity and delicate nature of crowdfunding fulfillment and offer service tailor-made to ensure your backers receive their rewards promptly, accurately, and intact.Subscription Boxes

If you run a subscription service, we can help you prepare orders in advance. We can kit and assemble subscription boxes in-house, using your own custom packaging if desired for an optimal unboxing experience. Plus, we guarantee timely and accurate delivery to your subscribers.Amazon FBA

If you sell on Amazon, you are probably familiar with the strict requirements of FBA. We offer comprehensive support for clients who need to prepare orders for Amazon FBA, making the hand-off an easy one.Custom Projects & More

Every business is different, and sometimes, it’s hard to know what you will need in advance. Our flexible fulfillment solutions cater to custom projects and unique requirements. That means we can respond to your needs and personalize your service accordingly.Get started with Fulfillrite in just 3 easy steps.

Sync to our Dashboard

Connect your store to our easy-to-use, cloud-based Dashboard.Ship us your goods

Send your product inventory to one or more of our warehouses.Let us handle the rest

Orders are promptly packed and shipped by our team, ensuring timely, pristine delivery to your customers.Check on your orders and inventory any time you like with our cloud-based Client Dashboard

Feature-rich yet easy to use, our cloud-based Dashboard integrates with popular online shopping carts and dozens of apps, so you can automate your business like never before.